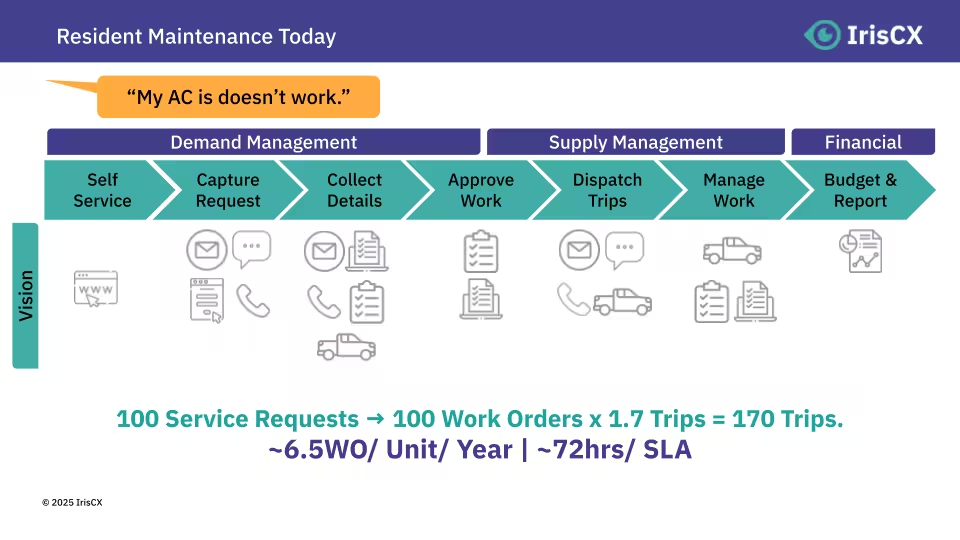

Property maintenance isn’t just about fixing what breaks—it’s about how efficiently and transparently you move from the moment a resident reports an issue to the moment the fix is complete, approved, and budgeted. For many teams, especially those working on-site, maintenance operations are intuitive, immediate, and often undocumented. For centralized teams, the process is systematized, tracked, and data-driven.

This step-by-step breakdown captures both realities—offering a guide that recognizes current behaviors while introducing scalable practices for higher efficiency and visibility.

Step 1: Self Service

The Resident’s First Move

Before ever contacting your team, many residents turn to Google, YouTube, GPT, or Resident chatbots to solve problems themselves. If they fail, they’ll submit a request—either through a resident portal, mobile app, or by simply calling, texting, or dropping by the office.

On-Site: Residents may prefer familiar personal channels. Staff receive calls or walk-ins and log issues manually.

Centralized: Requests are logged digitally from the start, often with suggestions to resolve basic issues independently.

Step 2: Capture Request

The Clock Starts Now

This is the moment a service request is officially received—via form, phone, email, SMS, or in-person. Whether logged in the PMS, CRM, or maintenance platform, this step initiates your service timer.

On-Site: Techs or leasing agents might get a call or hallway tap. Logging happens later—if at all.

Centralized: All requests are funneled into one system, triggering automated notifications and workflows. This is often a great place to consider Artificial Intelligence to enhance the data, respond or seek to deflect the request.

⏱️ This is when the response clock starts ticking.

Step 3: Collect Details

Clarifying the Problem (and Often the First Trip)

Now the real work begins. You start gathering context: photos, model numbers, symptoms, access instructions. In many cases, this stage includes follow-up calls, messages, or even the first trip to inspect the issue.

On-Site: Collection is often physical—techs go to the unit to understand what’s wrong.

Centralized: Coordinators may collect more info before dispatching, aiming to prevent wasted trips. This can be with phone, forms, notifications, text messages or TeleMaintenance applications.

💸 This is where costs begin—time, effort, and possible missed diagnoses.

Step 4: Process Tasks

Deciding What to Do and Who Will Do It

Here you decide: Is this a tech job? A vendor call? DIY? For many on-site teams, this decision is made instantly—often before the task is even entered into a system. In centralized setups, it’s where you notify the appropriate on-site team, pod, or vendor.

On-Site: This is instinctive and immediate. Whoever’s there handles it, often before documentation.

Centralized: This is a formal handoff step—often supported by AI when the data is good.

🧠 This step is often invisible to on-site teams but is pivotal for optimization and accountability.

Step 5: Dispatch Trips

Executing the Fix

This is when someone physically heads out to complete the repair. For small issues, this may happen during the “collect details” step. For larger fixes, it may involve grabbing parts, calling vendors, or even driving to suppliers.

On-Site: Trip is immediate. Closet check, toolbox grab, and off they go.

Centralized: Parts needs are confirmed first. Scheduled dispatch follows with proper prep.

🔧 This step is where the work becomes tangible—and efficiency matters most.

Step 6: Manage Work

Close, Document, and Inspect

After the fix, teams must close the task, document the work, and, in some cases, conduct a QA inspection. For on-site teams, this is often a low-priority, end-of-day chore. For centralized teams, it’s a standard practice.

On-Site: Documentation is minimal or delayed. QA is informal or driven by resident complaints.

Centralized: Real-time digital updates and inspections ensure quality and transparency.

📋 This is where you capture insights, resident sentiment, and resolution metrics.

Step 7: Budget & Report

Track the Financial Impact

This final step is where the labor, parts, vendor costs, and approvals are recorded, analyzed, and reported. It informs staffing, sourcing, and even capital planning.

On-Site: Financial implications are rarely connected to daily work—budgeting happens far downstream.

Centralized: Reporting is live, enabling proactive decisions on staffing, outsourcing, and operational ROI.

💰 This is where maintenance turns from activity into strategy.

Where Are Demand and Supply Still Bundled?

In many operations, especially at the site level, demand (what needs doing) and supply (who will do it) are bundled together—often leading to premature dispatch, incomplete data, or untracked costs.

Ask yourself: Where in your current process do demand and supply decisions happen simultaneously? Can you separate them for more clarity, efficiency, and accountability?